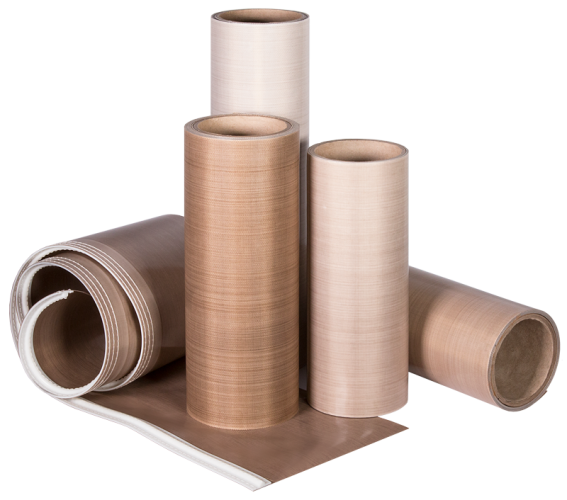

POROUS PTFE FABRIC

The Porous Series of PTFE Fabrics is specifically designed to control porosities thus allowing products to cure and out-gas through the fabric. This functionality makes it the ideal fabric for any chemical or composite curing application. Because of their unique properties, these fabrics are excellent for use in a wide range of applications, from the manufacture of polymers to a release medium for composite molding. They are specifically formulated to be breathable and maintain the non-stick properties offered by PTFE.

These fabrics are manufactured from woven fiberglass substrates that have been lightly coated with PTFE. They are food safe and FDA Compliant.

Typical Applications

Polymer Processing

- Manufacture of silicone rubber sheet

- Curing rubber & plastic foams and sponge

Aerospace, Communications & Military

- Composite mold release

- Curing rubber & plastic foams and sponge

Other Applications

- Insulation and protection

- Release sheets/separation materials

- Drying painted or lacquered products

Technical Data

Porous PTFE Fabric Specifications

| GENERAL INFORMATION | |

|---|---|

| Continuous Operating Temperature Range | -100° to 550° F |

| Substrate | Woven Fiberglass |

| Coating | PTFE |

| Color | Tan |

| Food Safety | FDA Compliant |

| Item Number | Nominal Thickness (inches) | Weight (lbs./ sq..yd.) | Tensile Warp (lbs./in.) | Tensile Fill (lbs./in.) | Edge Tear Warp (oz.) | Edge Tear Fill (oz.) | Full Widths (inches) |

|---|---|---|---|---|---|---|---|

| 27-03 | .003" | 0.12 | 56 | 32 | 13 | 9 | 38, 50, 60, 80 |

| 27-05 | .005" | 0.24 | 100 | 96 | 28 | 25 | 80 |

| 27-10 | .010" | 0.50 | 200 | 160 | 49 | 39 | 44 |

| 27-14 | .014" | 0.70 | 320 | 232 | 130 | 113 | 40, 80 |

| 27-25 | .025" | 1.30 | 520 | 472 | 225 | 225 | 50, 62 |

Please note: Additional thicknesses and styles are available upon special order.

What is PTFE?

Polytetrafluoroethylene (PTFE), a fluorocarbon plastic, is a plastic in which the hydrogen normally found in association with carbon in organic materials has been replaced with fluorine. The resulting polymer possesses a number of unique properties: inertness to chemicals, fire resistance (will not support a frame); excellent weathering resistance; low friction (second only to ice); superior anti-stick properties; flexibility; extreme heat and cold resistance; outstanding electrical, insulative and dielectric properties; and resistance to ultraviolet (UV), infrared (IR), microwave and radio frequency (RF).

Mechanical PTFE Fabrics are manufactured in 4 common thicknesses: 0.003″, 0.005″, 0.009″, 0.010″, and 0.014″