TYGON® A-60-G CHEMICAL DISPENSING TUBING

High-Performance Alternative to Rubber Tubing

Specially formulated for chemical dispensing, Tygon A-60-G tubing outperforms neoprene, EPDM and other general-purpose tubing in test after test, application after application. It will not weaken or crack after years of exposure to heat and ozone, providing longer peristaltic pump life in industrial and institutional cleaning-chemical dispensing applications.

Engineered for outstanding performance and on-the-job reliability, Tygon A-60-G tubing handles temperatures ranging from -75°F (-60°C) to 275°F (135°C), allowing the use of one material within a broad range of temperatures. It is heat sealable and can be joined without fittings. It also offers excellent resistance to inorganic fluids (acids and bases).

Tygon A-60-G tubing is available in standard vacuum sizes that will withstand a full vacuum (29.9″ [759 mm] of mercury) at 73°F (23°C). Unlike typical rubber vacuum tubing, Tygon® tubing resists the cracking and aging that are frequent causes of vacuum tubing failure.

FEATURES

- Superior weathering

- Abrasion resistant

- Outstanding flexural fatigue resistance

- Wide temperature range (-75°F to 275°F)

- Low gas permeability versus rubber tubing

- Ozone (300 pphm) and UV light resistant

Technical Data

TYGON® A-60-G Specifications

TYGON® A-60-G Chemical Test

Product Specs

| SPECIFICATIONS | |

|---|---|

| Color | Black |

| Temperature Ranges | -75°F to 275°F |

| (-60°C) to (135°C) | |

| Material | Tygon |

| Color | Black |

| Applications | •Soap and disinfectant dispensing |

| •Cleaning chemical transfer | |

| •Caustic chemical dispensing | |

| •Plating and etching chemicals | |

| •Glass and window wash systems | |

| •Vacuum pumps | |

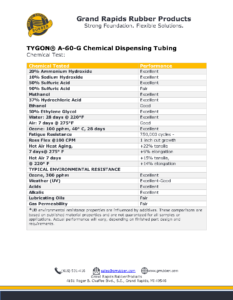

| Chemical Tested | Performance |

|---|---|

| 20% Ammonium Hydroxide | Excellent |

| 10% Sodium Hydroxide | Excellent |

| 50% Sulfuric Acid | Excellent |

| 90% Sulfuric Acid | Fair |

| Methanol | Excellent |

| 37% Hydrochloric Acid | Excellent |

| Ethanol | Good |

| 50% Ethylene Glycol | Excellent |

| Water: 28 days @ 220°F | Excellent |

| Air: 7 days @ 275°F | Good |

| Ozone: 100 pphm, 40° C, 28 days | Excellent |

| Fatigue Resistance | 750,000 cyles - |

| Ross Flex @100 CPM | 1 inch cut growth |

| Hot Air Heat Aging, | +22% tensile |

| 7 days@ 275° F | +9% elongation |

| Hot Air 7 days | +15% tensile, |

| @ 220° F | +14% elongation |

| TYPICAL ENVIRONMENTAL RESISTANCE | |

| Ozone, 300 pphm | Excellent |

| Weather (UV) | Excellent-Good |

| Acids | Excellent |

| Alkalis | Excellent |

| Lubricating Oils | Fair |

| Gas Permeability | Fair |

| Item Number | ID (in) | OD (in) | Wall Thickness (in) | Length (ft) | Min. Bend Radius (ft) | Max. Working Pressure 73° F (psi)* | Max. Working Pressure 180° F (psi)* | Vacuum Rating inHg at 73° F | Vacuum Rating inHg at 180° F |

|---|---|---|---|---|---|---|---|---|---|

| AFL00003 | 1/16 | 3/16 | 1/16 | 50 | 1/4 | 34 | 21 | 29.9 | 29.9 |

| AFL00007 | 1/8 | 1/4 | 1/16 | 50 | 1/2 | 19 | 12 | 29.9 | 29.9 |

| AFL00008*** | 1/8 | 3/8 | 1/8 | 50 | 1/2 | 34 | 21 | 29.9 | 29.9 |

| AFL00012 | 3/16 | 5/16 | 1/16 | 50 | 3/4 | 13 | 8 | 29.9 | 29.9 |

| AFL00013 | 3/16 | 3/8 | 3/32 | 50 | 1/2 | 19 | 12 | 29.9 | 29.9 |

| AFL00015** | 3/16 | 9/16 | 3/16 | 50 | 1/4 | 34 | 21 | 29.9 | 29.9 |

| AFL00017 | 1/4 | 3/8 | 1/16 | 50 | 7/8 | 10 | 6 | 29.9 | 15.8 |

| AFL00018 | 1/4 | 7/16 | 3/32 | 50 | 3/4 | 15 | 9 | 29.9 | 29.9 |

| AFL00019 | 1/4 | 1/2 | 1/8 | 50 | 3/4 | 19 | 12 | 29.9 | 29.9 |

| AFL00020** | 1/4 | 5/8 | 3/16 | 50 | 1/2 | 26 | 16 | 29.9 | 29.9 |

| AFL00022 | 5/16 | 7/16 | 1/16 | 50 | 1-1/4 | 8 | 5 | 20.2 | 10.1 |

| AFL00023 | 5/16 | 1/2 | 3/32 | 50 | 1 | 12 | 7 | 29.9 | 25 |

| AFL00026 | 5/16 | 13/16 | 1/4 | 50 | 1/2 | 28 | 17 | 29.9 | 29.9 |

| AFL00027 | 3/8 | 1/2 | 1/16 | 50 | 1-3/8 | 7 | 4 | 14.1 | 7 |

| AFL00028 | 3/8 | 9/16 | 3/32 | 50 | 1-1/2 | 10 | 6 | 29.9 | 15 |

| AFL00029 | 3/8 | 5/8 | 1/8 | 50 | 1-1/8 | 13 | 8 | 29.9 | 27.7 |

| AFL00032 | 7/16 | 9/16 | 1/16 | 50 | 2-1/4 | 6 | 4 | 5 | 0 |

| AFL00036 | 1/2 | 5/8 | 1/16 | 50 | 3 | 6 | 3 | 15 | 0 |

| AFL00037 | 1/2 | 11/16 | 3/32 | 50 | 2-1/4 | 8 | 5 | 20 | 10 |

| AFL00038 | 1/2 | 3/4 | 1/8 | 50 | 1-1/8 | 10 | 6 | 29.6 | 15.6 |

| AFL00045 | 5/8 | 13/16 | 3/32 | 50 | 3-1/4 | 7 | 4 | 10 | 5 |

| AFL00046 | 5/8 | 7/8 | 1/8 | 50 | 2-3/4 | 8 | 5 | 20 | 9.9 |

| AFL00053 | 3/4 | 1 | 1/8 | 50 | 3-1/2 | 7 | 4 | 13.9 | 6.9 |

| AFL00062 | 1 | 1-1/4 | 1/8 | 50 | 5 | 6 | 3 | 5 | 5 |

**Vacuum tubing sizes

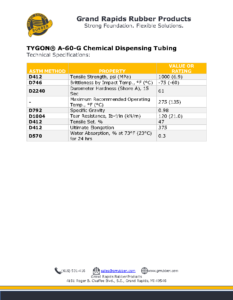

| ASTM METHOD | PROPERTY | VALUE OR RATING |

|---|---|---|

| D412 | Tensile Strength, psi (MPa) | 1000 (6.9) |

| D746 | Brittleness by Impact Temp., °F (°C) | -75 (-60) |

| D2240 | Durometer Hardness (Shore A), 15 Sec | 61 |

| - | Maximum Recommended Operating Temp., °F (°C) | 275 (135) |

| D792 | Specific Gravity | 0.98 |

| D1004 | Tear Resistance, Ib-f/in (kN/m) | 120 (21.0) |

| D412 | Tensile Set. % | 47 |

| D412 | Ultimate Elongation | 375 |

| D570 | Water Absorption, % at 73°F (23°C) for 24 hrs | 0.3 |